Airjet

Signature JF9100

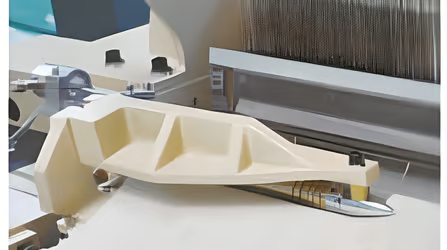

The rigidity of the frame and beam of the Signature JF9100 loom is strengthened, the whole machine has good stability, the beating mechanism is further optimized, the structure is more reasonable, and four connecting rod or six connecting rod can be used to beat the weft. When using six links to beat weft , it can extend the opening time of warp yarn, facilitate weft insertion, and is more suitable for weaving wide width loom fabric, and broadens the weaving scope of looms.

Signature JF 9100

Energy-saving and Cost-reduction

- Terminal auxiliary nozzle with pressure independently adjustable to enhance weft insertion and reduce consumption of air compressor.

- Stable weft insertion enables one air valve to work with two auxiliary nozzles, which contributes to Low energy consumption by less air-jet time compatible with high speed.

Stability and Reliability

- One piece of whole wallboard is applied with good anti-vibration and reliability to ensure the looms high speed, wider width and low noise.

- Both stability and reliability of the weft insertion systems are enhanced due to space narrowing down between auxiliary nozzles.

- With newly designed strong and tenacious framework, well balanced beating-up is realized through off center rockshaft upon little inertia moment 20% reduction of earthshock is obtained due to the control of vibration.

Intelligent Humanization

The adoption of new type display, new communication technology and remote control technology, relizes the high intelligence of the whole machine. It provides the superior operation to achieve high efficiency weaving production.

More Variable Shedding

Signature Airjet Loom can operate with electronic dobby CAM shedding, which ensures running smoothly, accurately and positively. Moreover, it can guarantee the max load is lower than the rated load.

Signature Airjet Loom can also run with electronic jacquard shedding driven by one vertical shaft.